Technology and Philosophy

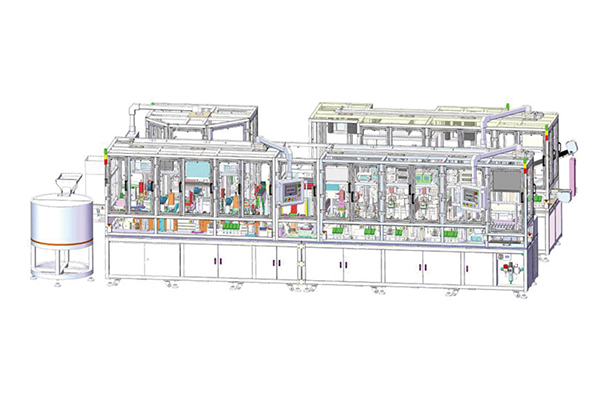

Advanced technology integration: This production line integrates the most advanced automation technology, utilizing advanced equipment such as robot assembly and intelligent sensors. The precision robotic arms on the production line can flexibly and accurately complete tasks such as assembly and testing, greatly improving the accuracy and efficiency of production.

Intelligent manufacturing concept: Every link from raw material storage to finished product delivery has achieved a high degree of automation and intelligence, which is a typical application of intelligent manufacturing concept in the field of automotive parts production. Intelligent sensors monitor the production environment and process in real-time, ensuring that each process meets the strictest standards and guaranteeing the high quality and stability of products.

production capacity

Efficient output: The production line operates with extremely high efficiency, with a high-quality PSS product being produced every ten seconds. With such a production speed, the annual output easily crosses the million mark, meeting the large demand for PSS products in the market and providing sufficient safety guarantees for the new energy vehicle and energy storage industries.

Product Features

Safe and reliable: PSS products have performance that does not degrade over time, are sturdy and durable, and can operate stably under various complex environmental conditions. They can effectively respond to challenges such as vibration and different weather conditions during vehicle operation, providing reliable guarantees for vehicle safety.

Accurate and controllable: Through strict control and uniquely designed triggering conditions, PSS can meet the requirements of various situations, ensuring accurate triggering at critical moments when power-off protection is needed, avoiding misoperation and missed actions.

Current compatibility: Regardless of whether the current intensity exceeds, falls below, or is normal, PSS can trigger perfectly, achieving circuit disconnection and effectively protecting the vehicle's electrical system from damage caused by abnormal currents.

Compact size: PSS has a constant size and is not affected by voltage, which can minimize component volume and facilitate installation and layout in the limited space inside the vehicle, without causing significant impact on the overall design and space utilization of the vehicle.

Easy to trace: PSS is a one-time activation product that ensures error free operation and facilitates post analysis. After a vehicle accident or malfunction, the status and triggering of PSS can be analyzed to understand the circuit situation and other information at the time of the accident, providing a basis for accident investigation and vehicle safety improvement.

Working principle

PSS uses pyrotechnic materials as a cutting power source. When it receives a trigger signal, it ignites the pyrotechnic materials through an internal ignition device, causing a rapid chemical reaction and instantly producing a large amount of gas, which pushes the internal piston rod to cut off the copper bar and achieve circuit cutting. It can actively cut off circuits with abnormal or short-circuit currents within 2ms and can be applied to voltages up to 1000V.

Company Address

Company Address Hotline

Hotline Url

Url